Metal bending equipment is designed to shape and form metal sheets or bars by applying precise force and control. It allows users to create accurate bends, angles, and curves essential for manufacturing and construction projects.

This equipment ranges from manual machines for small tasks to automated systems for industrial-scale production. Understanding the right type of metal bending tool is key to improving efficiency and achieving the desired metal shape.

Whether working with steel, aluminum, or copper, metal bending tools provide the necessary strength and accuracy to handle various thicknesses and materials. Choosing the appropriate equipment depends on the project’s size, material, and complexity.

Types of Metal Bending Equipment

Metal bending equipment varies by operation style, capacity, and automation level. Some tools depend on manual effort, while others use hydraulic power or computerized control to achieve precision and efficiency.

Manual Metal Benders

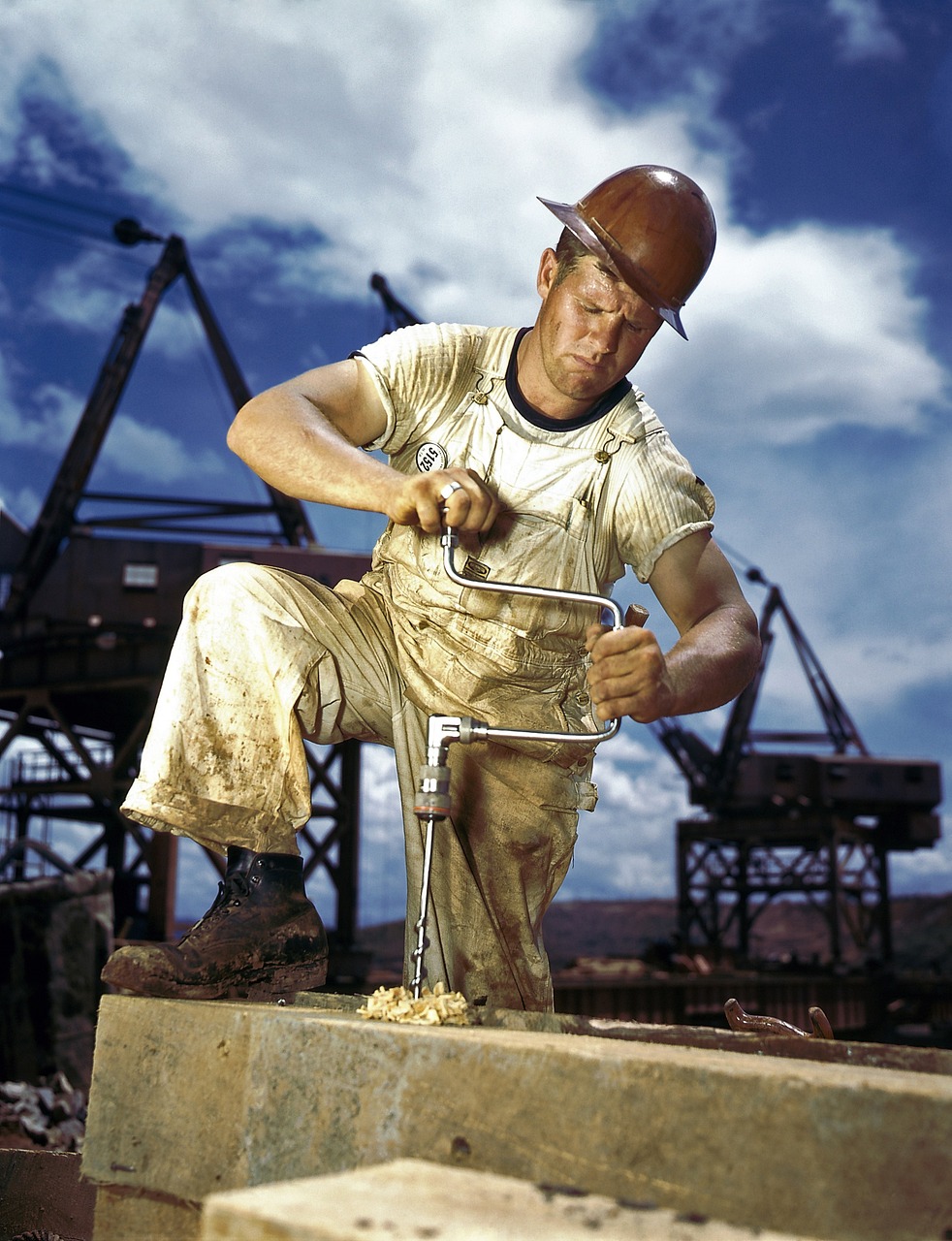

Manual metal benders rely on physical force applied by operators to bend metal sheets or rods. They are typically simple, portable, and suited for smaller jobs or low-volume production.

These tools include hand brakes, tube benders, and angle benders. They are cost-effective but require skill and effort for accurate bends.

Manual benders are limited by the thickness of metal they can handle, generally working best on thinner materials under 6mm. Setup time is quick, making them practical for on-site or custom work.

Hydraulic Bending Machines

Hydraulic bending machines use fluid pressure to apply force. This allows them to bend thicker and tougher metals with less physical input compared to manual tools.

They offer precise control over bending angles and pressure, making them suitable for medium to heavy-duty applications. These machines range from simple hydraulic press brakes to multifunctional units.

Hydraulic systems provide consistent force, reducing human error and fatigue. Operators can adjust speed, angle, and pressure, improving repeatability.

CNC Metal Bending Systems

CNC (Computer Numerical Control) metal bending systems automate the process with programmable controls. They deliver high precision, repeatability, and complex bending sequences.

These systems are ideal for high-volume manufacturing and intricate designs requiring exact angles and multiple bends.

CNC benders integrate with design software, allowing automatic adjustments and error checking. They minimize material waste and optimize production time.

Costs are higher, but CNC systems increase efficiency and accuracy for demanding industrial environments.

Key Features and Considerations

Metal bending equipment varies widely in function and application. The choice depends on the specific materials being worked on, the precision required in shaping, and the safety features designed to protect users.

Material Compatibility

Metal bending tools must match the type and thickness of the metal. Common metals include steel, aluminum, copper, and brass, each with different bending tolerances.

Equipment designed for thin aluminum sheets may not handle thicker steel plates effectively. Knowing the allowed bending radii and force limits ensures the machine won’t damage the metal or itself.

Some machines offer adjustable pressure settings and interchangeable dies to accommodate different metals. This flexibility helps manufacturers avoid frequent equipment changes, reducing downtime.

Precision and Accuracy

Accuracy in metal bending is critical for parts to fit correctly in assemblies. Machines with CNC controls provide programmable precision, often achieving tolerances within ±0.1 mm.

Manual equipment relies more on operator skill and can result in greater variation. Repeatability is important when producing multiple identical parts.

Features like digital angle readouts, back gauges, and automated stop points contribute to consistent results. These reduce waste and rework in production environments.

Safety Mechanisms

Safety is essential due to the high forces and moving parts involved. Modern metal bending equipment includes emergency stop buttons and safety guards around pinch points.

Light curtains or sensor arrays can halt operations if a body part enters a dangerous zone. Lockout/tagout capabilities ensure the machine cannot start during maintenance.

Operators must also be trained in proper use and protective gear. Good safety design minimizes the risk of injury without hindering productivity.

Leave a Reply